High-Performance Materials: Carbon, Basalt, Aramid, and Fiberglass Explained

If you are considering making something but here to meet the financial rebar matric, we typically apply bulky items like metal or stone. These materials offer great resistance and have a long life. However, there are materials that stronger and lighter than this. This type of materials named as high-performance materials. Carbon, basalt, aramid and fiberglass are some high-performance materials examples. They are some of the greatest materials as well, with each having its specific properties that make them best to use in various scenarios.

Carbon is super strong yet lightweight. It is excellent for parts and products like aerospace, racing car or sport gear since it is incredibly strong. Carbon is made up of microscopic fibres that are bound together by a magic glue. When those small fibers mix with glue they form an extremely rugged and tough material. It is for this reason that the industries also opt to have their products in carbon because it offers excellent load-bearing properties.

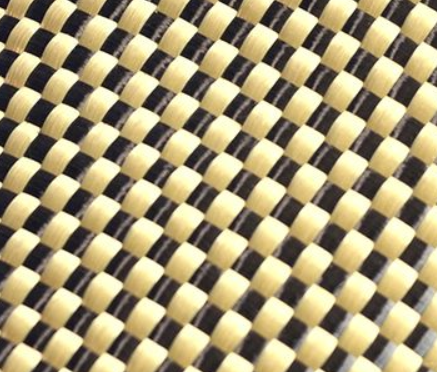

High performance material: Basalt Made in the form of melted down volcanic rocks that turn into fibers. These fibers are then woven into a strong but lightweight cloth that has many uses. Basalt is incredibly tough and very resistant to wear and will not tear over time which makes it a perfect material for long-lasting applications. When we talk about some construction or even in clothing you may find basalt used.

Aramid is a very strong and tough material. It consists of long, thin fibers which are stitched together to make a particular fabric. This fabric is able to withstand a lot of abuse and it can last for years. It is also heat resistant which allows it to be utilized in high temperature scenarios. Aramid fiber products is utilized in essential items such as bulletproof vests, racing suits and firefighter gear. These applications really help to illustrate how aramid can be so indispensable and successful in keeping people safe.

The material has a high efficiency Fiberglass-same It is a light material and composed of microscopic glass fibers being woven together. It is tough for withstanding high heat and corrosion final result of which it brings a lot in usefulness. Fiberglass is frequently used in marine and aircraft construction, trains scale models of it are also very popular. With its versatility, it is present at different places to make things lightweight but with strength.

Resisting Heat and Chemicals

Both manufacturing and welding are parts of a stiffer stainless structure such as in areas subjected high heat or harsh chemicals, which makes use of high-performance materials. They are made to withstand the harshest elements, Carbon, Basalt, Aramid and Fiberglass are just fine with these harsh conditions.

Carbon — It resists high heat well. This is why it is frequently utilized in components used within planes or other heated-flight vessels as temperatures can be immensely high. It can also withstand rust well, so it is commonly used in harsh environments where other materials may corrode.

It resistant to rust and high heat (basalt). It is commonly employed in severe chemical or high heat applications, e.g. the rear of brake pads that will be at very high temperatures when used by a car as well as restraints on military clothing such a flame-retardant coverings for Sikh soldiers with turbans. The hardness of basalt has made it a favorite with the automotive industry.

Aramid well known for its resistance to moisture absorbency and high heat An example this is critical for firefighter gear since the temperatures can go to really high values. In addition to this, aramid fiber fabric is resistant to chemicals and hence used in numerous types of industrial jobs where safety as well durability are both critical.

It is also agencies capable of resisting high heat and rust as well. Which is why it makes a really good choice for boats and aircraft, since it is super lightweight but still able to withstand being tossed around. Fiberglass also does not absorb water, which makes it ideal for use in swimming pools and other water-related applications. On top of that, this product is designed to be water-resistant, great when you are near the pool.

Durable, Versatile & Flame-Retardant

Strong and flexible — Those are the words that pop up in our mind when we hear high-performance materials. They are also fire-resistant and have some strength power, one which can be extremely helpful in a gamut of ways.

Carbon is very hard and has a High impact resistance. It is also pliable, which makes it a great material for bike frames. While the firm plastic is, uh…firm and able to hold its shape or support weight and stuff; a softer material has give in it — enabling objects designed for this device-bin blend of strength but movement. Carbon is non-combustible hence not readily ignites. This is a great choice for fire‐risky applications.

It also has the qualities of being strong and flexible. It is good for high heat and fire obviously, which can be useful in things like fireproof clothing that must resist such. With its durability, you are getting flexibility that can be utilized across many applications for safety and reliability.

Aramid is a super strong material, which withstands years of abuse. It is also more stretchable, which makes it ideal for use in racing suits where motion counts a lot. Aramid has a high resistance to fire which is why it's commonly used in firefighter gear. This is to maintain the busy-bees in power and save their faces from burning or getting injured!

It is composed mainly of strong and flexible fiberglass. They can withstand extreme conditions like fire, which is why they are widely used in construction applications. Additionally, it is implemented in the construction of boats and airplanes which once more shows its durable properties. Fiberglass is widely used in various sectors due to its ability for withstanding different challenges.

eHSF 700: for High Performance at Reasonable Prices

These high-performance materials can take essentially any form, literally. Versatile – this one is being sold short simply because it can do so many things. They are also generally cheaper than other materials, making them a great option for several industries. One of the most important aspects to consider while selecting materials for production and manufacturing is there affordability.

Carbon: Airplane parts, sports gear and more It is not very expensive either, also making it a favorite in many regions. This means companies can produce quality products without spending excessive money.

The compound that the researchers are currently testing in a demonstrator is basalt, which stands problematically behind some brake pads and other automotive uses. It is also very cost effective, so it suits many different industries. Basalt is being used by companies who manufacture car parts for the extra strength without high cost.

Racing suit to firefighter gear, aramid is great material for most applications. It is not too expensive either, which makes it valuable for many applications. This allows manufacturers not to spend the moon without banging out robust and secure products.

Fiberglass has multiple uses throughout the various types of applications. You can use it for construction, sports gear and other goods. Attractive and economical, powder coating is ideal for numerous applications across many industries. But, since it is so cheap and versatile in its usage a whole host of manufacturers continue to use fiberglass for their projectiles.

Carbon Vs Basalt Aramid Fiberglass

High-performance materials can be produced in many ways.【Adobe Stock】 Carbon, basalt, aramid fabric and fiberglass are each incredible products that bring something different to the table.

Strong and lightweight, carbon is the material of choice for a lot more than just race cars or prosthetic limbs. This is mainly used in aeroplanes parts, racing cars and all types of sport gear where durability matters the most.

Basalt is famed for its durability and resistance to wear. In the production of brakes or other automotive components, it helps maintain vehicle safety over time.

Kevlar is also well known to be extremely strong and resistant. It is commonly found in firefighter gear, racing suits and other industrial environments requiring solid structural strength. Aramid, therefore, is vitally important for saving lives in hazardous missions.

Being both versatile and cost-effective, fiberglass is a popular choice. Therefore, it is frequently utilized in construction and the manufacture of boats and airplanes. This characteristic makes it one of the most common materials in various industries due to its durability and versatility.

To conclude, in many fields of industry environmentally friendly type carbon fiber fabrics as smart materials such as aramid-fiber will be the gems. The part is prized for being strong, durable and lightweight. They are also resistant to high heat, rust and fire. Through studying these materials, we can learn how they work and what makes them so important. Having some basic understanding of these materials helps us to see the technology and engineering in our everyday products.

Comments

Post a Comment